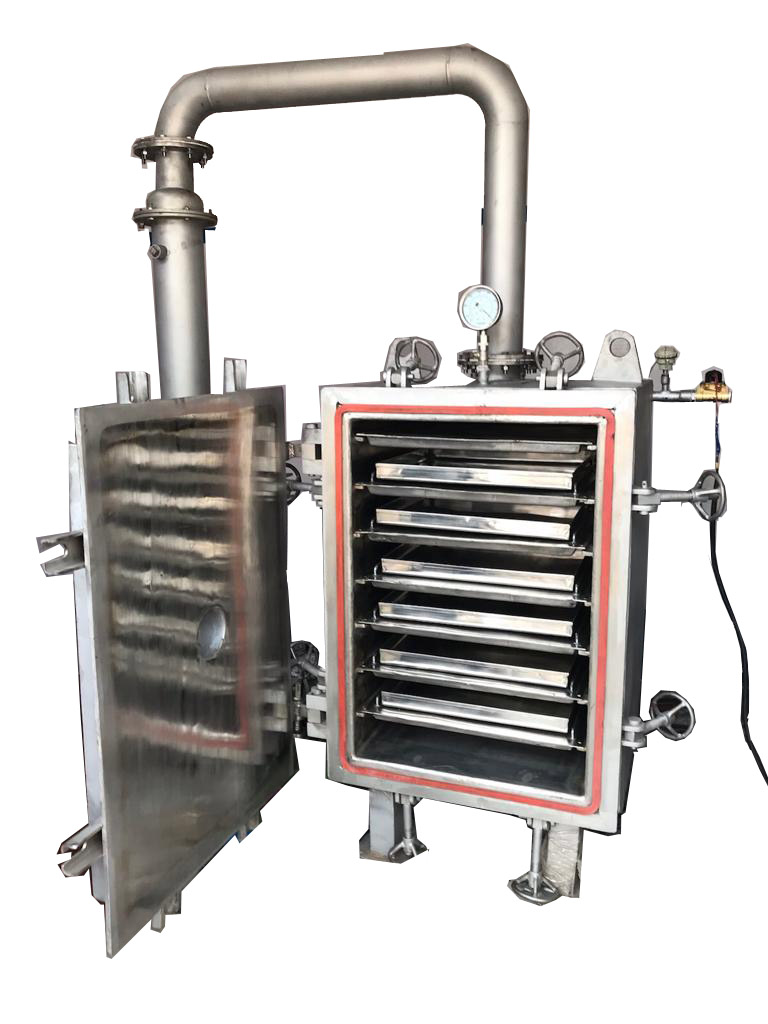

Product Details:

| Minimum Order Quantity | 1 Piece |

|---|---|

| Brand | BPE |

| Body Material | Stainless Steel |

| No. Of Tray | 6 |

| Power Source | Electric |

| Loading Capacity | 20 - 50 Kg |

Additional Information :

- Item Code : BVTD

- Pay Mode Terms : L/C (Letter of Credit),T/T (Bank Transfer)

- Port of Dispatch : Nava Sheva Mumbai

- Production Capacity : 100 Units/Month

- Delivery Time : 4 Weeks

- Packaging Details : Wooden Packaging

BPE Process Equipment Pvt. Ltd. is leading Vacuum Tray Dryer Manufacturer, Supplier In Pune, Bangalore/Bengaluru

Drying thermally sensitive materials that are quickly resolved, polymerized, or harmed by higher temperatures is appropriate for vacuum tray dryers. Prior to drying, which allows nothing to penetrate the product, sterilisation can be carried out. The static vacuum drier prevents configuration damage to the drying materials and is hence used in the chemical, food, and pharmaceutical industries.

Features :

- Heavy strength SS 316 flange and stiffeners with thick SS 316 plate for the main body and vacuum chamber.

- Heavy strength SS 316 flange and door-thick hemispherical SS 316 plate.

- Shelves Hollow type pads with baffles and SS 316 sheet.

- SS 304 Condenser (shell and tube) and Receiver with Flo Glass and Isolation Valve in the middle to check condensation

- SS 316 trays with rounded corners and edges that do not fold in the rear.

- Explosion Vacuum chamber's Vent/Rupture Disc

- At the hot water inlet is a digital temperature controller (FLP) with a solenoid-controlled pneumatic valve.

- There is a port for validation on the body.

- At the HVAC input and outflow is a digital temperature indicator (FLP).

- Vacuum gauge of the digital variety with Digital Temperature Indicator (FLP) in the vapour line

- Steam line pressure relief valve

- View On the body, receiver, and dorr of the vacuum chamber there is glass or light glass.

- Transparent silicone door gasket

- There is a nitrogen purging valve in the vacuum chamber.

- On a vacuum chamber, there is a vacuum break valve.

- Drain valve for the receiver and vacuum chamber.

- Temperature accuracy is plus or minus two to three degrees.

- Finish 180 grit mat finish on the outside and 320 grit internal mirror polish.

Optional :

- Condenser and receiver may be made with SS 316 as opposed to SS 304.

- Insulation covers the exterior of the vacuum chamber, excluding the door. Removable SS 304 panels enclose and cover the insulation. All around the body/vacuum chamber flange, there is skirting or a wall panel.

- Censor-equipped validation port

- Steam heated hot water system with an insulated MS tank, SS 304 steam radiators, and an electric circulation pump with FLP motors and controls.

- Vacuum pump with an FLP motor (2 stage water ring).